Rice Bran Stabilised

Western Technology’s product range of piping, shutters and valves covers square piping for the gravity flow of grain and other free-flowing products

Product Overview:

STABILISED RICE BRAN

Rice bran is the residue of polishing the rice grain without the husk.

Rice bran, a by-product of rice, is rich in protein (15-18%) and energy and contains high levels of natural vitamins and essential minerals. These qualities lead to high demand for rice bran as an ingredient for animal feed, and it is widely used for this purpose around the world. Bran accounts for 4-9% of the weight of paddy rice, varying according to location and degree of milling.

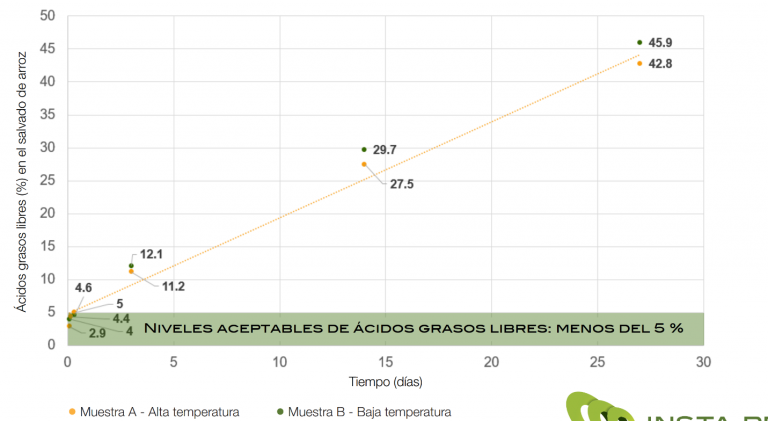

Rice bran contains good quality oil that is suitable for use in salads or cooking, similar to peanut, cottonseed, or corn oils. The amount of oil in rice bran ranges from less than 10% to more than 20%, depending on the milling process, the amount of contamination of the bran with husk and broken pieces of rice, and whether the bran is obtained from raw or pre-cooked rice. Typically, rice bran contains about 15% oil when relatively free of hulls, a level approaching that of soybeans, which contain 18-20% oil. Rice bran has a unique and powerful enzyme system, which is activated during the milling process causing the oil to hydrolyze rapidly into free fatty acids (FFA*) and glycerin. Unmilled paddy and brown rice oil are relatively stable because the potentially degradative lipolytic enzymes are found mainly in the testa and transverse cells of the seed coat, while most of the oil is stored in the aleurone cells and germ. When physical separation is interrupted by milling operations, naturally high lipase activity leads to hydrolysis of the neutral fat. The rate of hydrolysis varies with temperature and other factors but can lead to approximately 30-50% of the oil being converted to FFAs within a week under tropical storage conditions.

Scientists have found that harmful enzymes in rice bran can be deactivated by heat. When rice bran is kept at an elevated temperature for long enough, the enzyme action can be slowed down or even completely stopped. As in other enzyme inactivation processes, the degree of inactivation increases with increasing temperature, humidity, and time of exposure to heat. In stabilized rice bran, the oil does not degrade even when the bran is stored for several months, and the FFA content remains fixed at the level it was at the time of stabilization. Therefore, if a bran containing low levels of FFAs is stabilized, it can be stored and later extracted to produce oil for food uses.

Rice bran stabilised by extrusion can remain stable for up to 5 months and contains highly digestible amino acids as well as natural antioxidants.

Benefits:

- Sterilisation and pasteurisation

- Inactivation of enzymes

- Rapid enzyme deactivation

- Improved nutrient digestibility

- Free fatty acids levels ≤5

- Shelf life of 5 months

High shear dry extrusion stabilises the rice bran.

Due to the instability of the lipases in rice bran, it must be stabilised within a few hours after milling to avoid rancidity.

Rice bran extruded at various times after milling :

– Rice bran, when not stabilised by extrusion within 8h after milling, becomes rancid and is no longer an acceptable ingredient.

– Rice bran can be used as an ingredient for aquatic, poultry, equine and swine feeds.

– Antibiotics reduce beneficial intestinal bacteria, while extruded rice bran increases “good” bacteria, acting as a prebiotic fibre.

The crude analysis of rice bran contains:

High Quality Oil*: 15-22%**

Crude Protein: 15-18%**

Fibre: 7-10%**

(*) Oil is relatively stable in unprocessed rice.

(**) The difference in range is due to variation in husking efficiency.

PROBLEMS:

- If not stabilised within 8h it cannot be used for feed.

- 8h after milling, the oil in the bran degrades, forming high levels of fatty acids. We will have less than 5% fatty acids if it is stabilised within 8h after milling.

- Bran that has undergone lipolytic degradation causes problems in the digestion of cattle.

- The higher the fatty acid levels, the lower the amount of recoverable edible oil.

- The oil contains 1-2% free fatty acids (FFAs) just after grinding.

- <5% FFA is desired in crude oil for economically viable refining.

- A few hours after milling, FFAs reach unacceptable levels (>5%).

- The higher the levels of FFAs in the oil, the higher the levels of refining losses (refining losses are 2-3 times the % of FFAs).

- CONCLUSION: It is important to keep FFA levels as low as possible right after milling to achieve high bran and oil quality.

- During milling lipolytic enzymes are activated:

- Causing hydrolysis of the oil to FFA.

- Rancidity develops within a few hours.

- Bugs appear within a week with hydrolysis at 30-50% (depending on moisture content).

- Rancidity affects rice bran quality and is impacted by:

- Hydrolysis or lipolysis, because it affects the action of the lipase enzyme that generates FFas (FFAs value).

- Oxidising or oxidation, by the deterioration of the unsaturated FFAs present (Peroxide value).

HOW TO SOLVE THEM:

Immediately stabilise with Western Technology’s high friction dry extruders.

For increased FFAs = increased oil extraction

Keep Peroxide values low

Notes: Stabilisation does not improve any degradation that has already occurred. Y

stabilisation does not stop oxidation but significantly delays it.

Our extruders and coolers have the following characteristics:

1-2 Tm/h Extruder + Cooler: 4,5mx3mx10m (height, width, length).

3-4 Tm/h Extruder + Cooler: 4,5mx6mx15m (height, width, length)

With high friction dry extruders, the bran remains stable for up to 5 months.

Benefits:

Rice millers can export stabilised bran, accessing new markets.

Millers will control when to sell = higher prices.

High quality rice bran for animal feed and oil extraction.

Stabilised rice bran has two market categories:

Feed: Pig, poultry, equine, aquatic, deer.

Human Food: Oil, flour.

Western Techonology’s rice bran stabilisers do not require added water, steam injection or external heat, they cook by converting the mechanical energy of the screw into frictional and shear heat, because granular material is compressed and forced through an orifice. This process has been widely used to mix and cook cereal grains and oilseeds in food production.

Western Technology’s rice bran stabilizers have the following advantages:

The equipment is available as standard production equipment

They are not dependent on steam as is the case with other means of stabilisation, but can be used with electricity currently available at rice mills, in contrast to steam which is only available at some mills, and unlike the use of steam, final drying requires no more than a chiller.

- The equipment is simple to install and operate.

- The equipment is adaptable to a wide range of sizes without serious economic losses.

All these reasons make this technology especially attractive for use in both small and large rice mills found in developing countries.

Extruders

Western Technology’s dry extruders generate heat through friction to accomplish numerous processes including: cooking, expanding, sterilizing, stabilizing, dehydrating and texturizing. The extruders can be either high hear which create various pressures and temperatures resulting in quality nutritional feed and food ingredients.

High shear dry extrusion is an economical and easy to use operation that offers unlimited processing opportunities.

Features:

- Rigid and compact structure

- Highly cost effective

- Versatile

- Easy to use

- Superior quality ingredients

Coolers

Our coolers remove heat and steam from extruded flour products before storage. This unit can be used with various combinations of extruders and presses and is an important component in producing and maintaining high quality extruded flours.

Features:

- Economical cooling of extruded flour products.

- Available in mild steel or stainless steel construction.

- Optional drum guarding available.

Oil Presses

Oil presses are ideal for the mechanical extraction of oil from oil bearing seeds. When combined with high-cost extruders, they form a unique oil extraction system. The entire process, from extrusion to processing and discharge of oils and meals, is continuous. This economical and user-friendly operation offers a wide range of processing possibilities. The mechanical system chemical-free used is ideal for processing organic, speciality and identity preserved oilseeds.