Chillers

Cold storage is especially beneficial for rice, corn, wheat, barley, soya bean, sunflower seed, sorghum, cottonseed, green coffee, alfalfa granules, and compound feed, … Ideal for seed conservation.

Product Overview:

We have equipment for refrigeration of cereals, seeds, and granulates.

Cold storage is especially beneficial for rice, corn, wheat, barley, soya bean, sunflower seed, sorghum, cottonseed, green coffee, alfalfa granules, and compound feed, … Ideal for seed conservation.

The use of grain cooling and air dehumidification systems is especially recommended for facilities in countries with tropical climates, due to the high humidity and average annual temperature, for facilities with long storage periods, and for storage of hygroscopic grains such as rice that absorb moisture from the air.

It is applicable in silos and warehouses. In the case of silos, the refrigerator is connected in place of the aeration fan. Its installation is usually immediate, not requiring additional work. In the case of warehouses and warehouses, there must previously be a special system of air conduction, either above or below the pavement. Our technical department will advise you in this regard for the conservation of grains.

The cold air produced by our equipment is conducted to the lower part of the silo. This air begins to cool the grain of the lower layers, pushing the heat, which crosses the entire mass of grain upward absorbing its heat and escaping in the form of hot air through the upper openings of the silo. The cooling ends when the air escaping from the grain mass is cold. In the case of refrigeration of warehouses, the process is analogous to that which takes place in silos. Cereal is a bad conductor of heat, that is, it acts as a good insulator. The heat radiation on that cold grain, even inside a metal silo or warehouse, has little influence. Therefore, it does not require isolation for optimum grain conservation.

Advantages of the conservation of seeds and grains

- Avoids the typical problems of the conservation of seeds: heat development, insects activity, product fermentation, molds, toxins, weight loss because grain metabolism, water condensation.

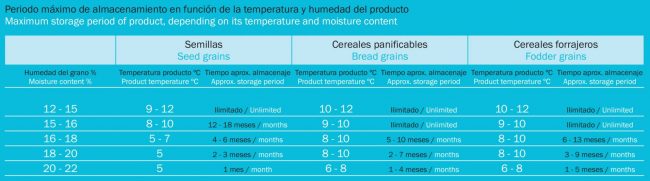

- Grain chilling allows higher grain moisture contents, without risk. With the use of cooling procedure, expensive, dangerous chemical fumigation is avoided.

- The product is stored in the best possible conditions. Operating costs of grain chilling are cheaper than storage costs with traditional systems.

- Typical payback for our equipment is achieved during the first/second year of use.

Refrigeration for Agroindustrial Processes

Apart from the standard program for the manufacture of cereal refrigeration equipment, on-demand we design and build equipment for other types of applications where the air is required under controlled hygrometric conditions, regardless of the environmental climate.

An example is the use of air treated with our equipment in chillers of various products such as nuts and snacks after the process of roasting, frying, etc. This allows the product to cool down to reach safe temperature levels, which makes it possible to immediately pack the product at the end of the process without quality losses due to excessive temperature and its undesired effect on oils and fats.

Use for drying

Another successful application is the use of equipment for drying processes – using temperate and very dry air – of very delicate products, such as seeds. The drying process is carried out without thermal shock, which guarantees to dry without damage to the product.

Another common use is the use of equipment for the maintenance of certain temperature and humidity conditions inside cold rooms.

In general, our equipment can be used in innumerable processes where it is required a clean air jet to humidity and temperature controlled with high precision, and its application is usually immediate, without requiring expensive fixed installations or civil works.