Tempering Silos

Rice is a hygroscopic grain it adjusts its humidity to that of the surrounding atmosphere depending on the temperature, that is why tropical areas must be treated in a more special way to achieve good quality and high yields in our product, and Western Technology offers the best solutions.

Product Overview:

In the drying of cereals in tropical areas, the use of tempering silos is highly recommended, if not essential. This is especially true for rice, perhaps the most difficult cereal to dry due to its peculiar drying characteristics.

Rice is a hygroscopic grain it adjusts its humidity to that of the surrounding atmosphere depending on the temperature, that is why tropical areas must be treated in a more special way to achieve good quality and high yields in our product, and Western Technology offers the best solutions.

When we use only the dryer, we heat the air and pass it through the grain to reduce its humidity. As a result, the grain will come out of the dryer hopper hot, so we must use some of the modules of the dryer to cool the grain and avoid many problems.

- If we cool in the dryer cool sections, we are cooling with external air, which in areas with high temperatures and high relative humidity, such as Vietnam, will not be sufficient for optimum storage.

- On the other hand, drying and cooling quickly will produce a high percentage of cracked grains on the inside (which we will not be able to see with the naked eye, but we will see when the grain arrives at the mill and our percentage of broken grains is much higher).

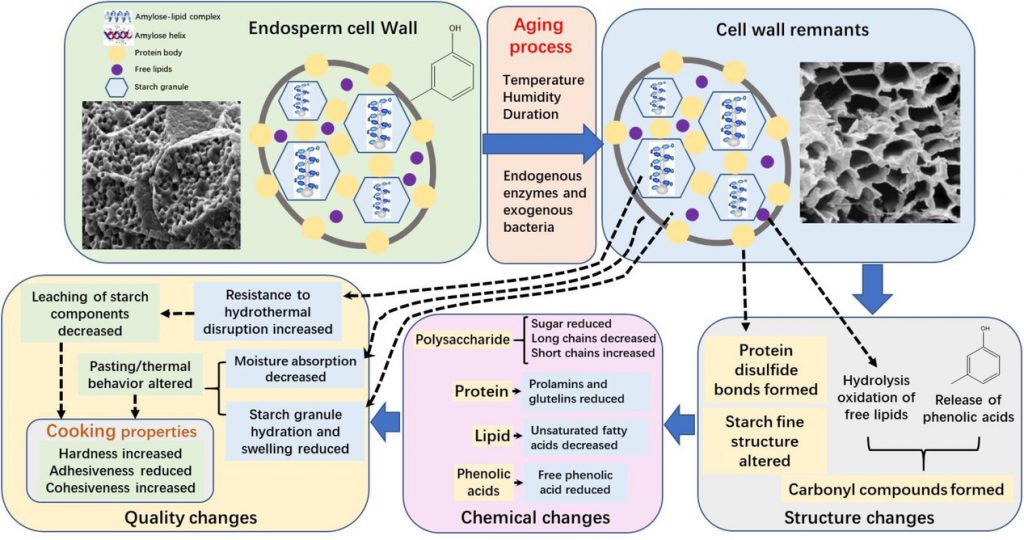

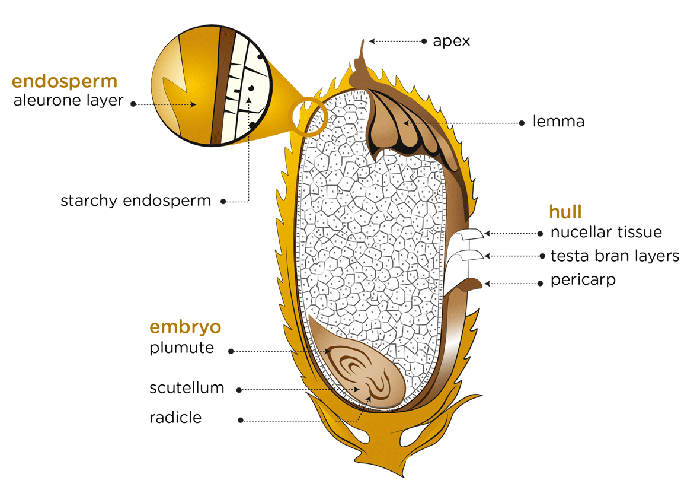

Why does the grain crack?

During the drying process, moisture is initially extracted from the external layers of the product, giving a moisture gradient from the center to the periphery in the kernel. When the gradient is too large, internal stresses cause cracking, which will subsequently result in a high percentage of broken kernels during handling. The higher the initial moisture content or grain size, the higher the stress.

Grain treated under these conditions greatly reduces its chances of long-term storage and increases the likelihood of tempering.

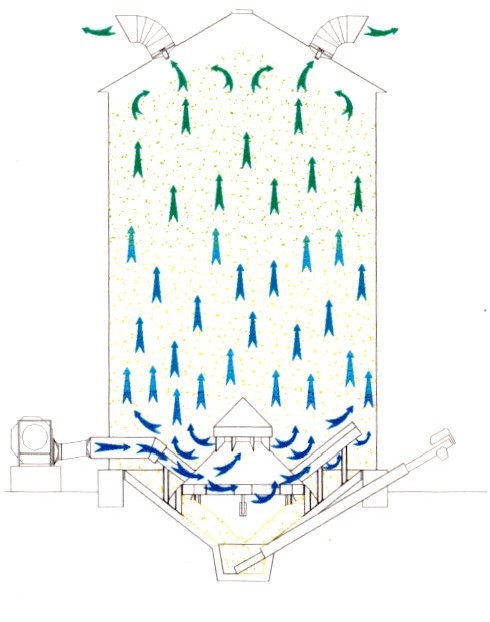

All these problems are minimized with Western Technology’s temperature control silos (tempering silos).

What happens when we use Western Technology’s Tempering Silos?

After many years of SAN JOSE’s experience in Spain, it has been proven that the quality of the product increases if the cooling is carried out with an intermediate resting period (tempering) and a long cooling period at room temperature, compared to cooling in the dryer column. But everything has a scientific explanation, and it is very simple. In the tempering silos, the grain remains at rest so that the grain is given enough time for the internal moisture (which is the most difficult to dry in the dryers) to migrate to the outermost layers, facilitating the final drying and eliminating the internal stresses that occur in rapid cooling, while at the same time the mass of grain tends to be homogenized.

Benefits of using Tempering Silos:

1. Increase the daily capacity of the dryer by 30 to 40%, considering that the last points of humidity are the most difficult to eliminate, due to the effect of the lower water diffusion speed and the application as a drying area of the previously applied cooling.

2. Significant energy savings in the Dryer + Tempering Silo set-up (around 30 to 40%) as the last degrees of humidity in the grain are removed during the tempering process without using heat. And these last degrees are the most complicated and costly in terms of energy.

3. We will obtain a final product with 50 to 60% less damaged grains (cracked or fissured), increasing its chances of being handled without breakage.

4. We will obtain a product with greater shine and final quality.

5. Higher oil yield in the case of oilseeds.

6. Correctly cooled grain increases the possibility of long storage periods and notably reduces tempering.

7. Less exposure of the grain to the action of combustion fumes and residues (they are deposited on the grain), reducing the risk of contamination by BAP (3-4 Benzopyrene), a substance with proven carcinogenic properties and for which certain countries have already implemented the relevant legislation.

8 Finally, we can compensate to a certain extent for the higher costs we will have to incur for this type of technology by using the tempering silos as storage silos when our campaigns come to an end.

9. They can be used for a second drying cycle if necessary if we cannot afford to reduce the humidity continuously. Western Technology will always try to design its industrial plants to avoid having to recirculate the product two or three times in the dryers, to achieve a continuous type of drying.

Our customers can be assured that Western Technology has mastered this technology and will provide you with the right machinery to dry your grain. Not all our competitors really know how to design the system to make it really work and be efficient. SAN JOSE has transferred to us their 40 years of experience using these systems for drying rice, maize, sunflower seeds, soya beans, etc… Whenever possible, Western Technology will offer its customers an installation design suitable for Continuous Drying, without having to recirculate the grain through the same dryers several times and having to stop the product reception process.

Why are we able to reduce the moisture content of the grain in the tempering Silos?

The reduction of moisture in the grain during the aeration process is achieved because the warm, moist grain is in equilibrium with the air between the grains, which is also warm, but saturated at that temperature. If we introduce a mass of air at room temperature countercurrent into this mass of grain, it will tend to heat up and its relative humidity content will drop, producing a moisture-temperature exchange that will break the moisture equilibrium inside the silo and the air will begin to capture the moisture that the grain is giving up to the micro-atmosphere between the grains. This transfer process takes place until the insufflated air is in equilibrium with the mass of grains, which can be said to be at rest and the process of water migration from the internal areas of the silo towards the caryopsis is underway.

Why are tempering silos more expensive than normal silos?

The tempering silos have their characteristics for the work they perform. They are NOT conventional silos and that is why their price is higher.

- They have a special unloading system.

- They use a greater number of control sensors.

- They use special aeration systems.

- They must have a greater number of accessories for correct operation.

- And they are specifically reinforced silos.