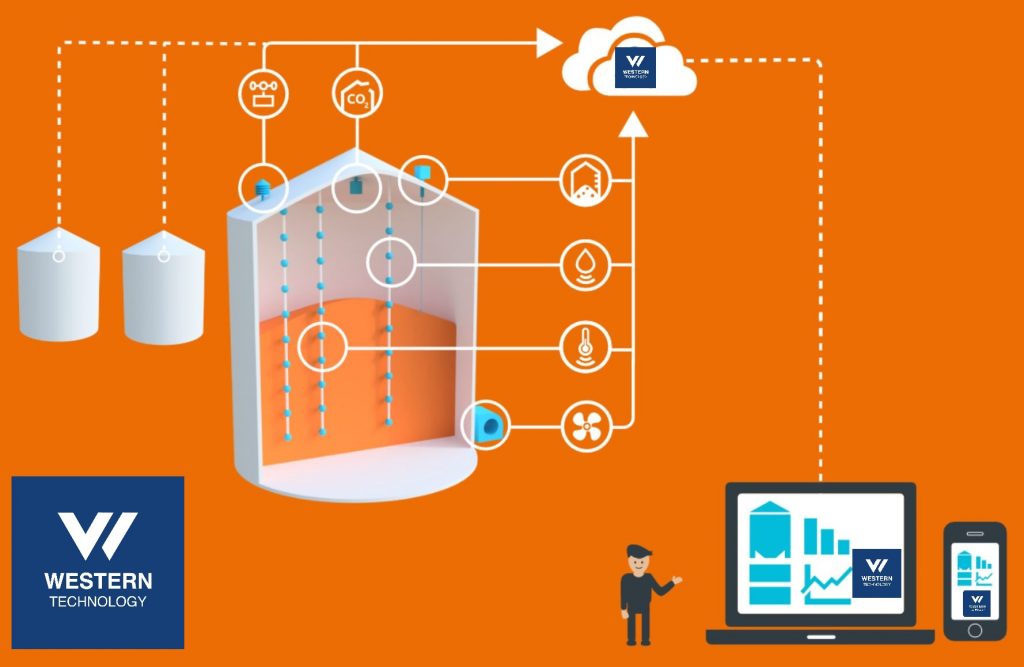

Grain Silo Monitoring

Real-time monitoring with valuable and reliable data helps you make the best decisions.

Product Overview:

To detect potential grain quality problems during storage, the condition of the grain must be monitored on a regular basis. Real-time monitoring with valuable and reliable data helps you make the best decisions.

Sensor Types:

Temperature Monitoring

Avoid spoilage in your grain detecting hotspots

Check temperature regularly until target temperatures are reached. Lower temperatures allow grain to be stored at a higher moisture content. Insects, mites, fungi and micro toxins thrive in higher temperatures.

Moisture Monitoring

For better storage quality and safety

Our grain monitoring systems offer moisture and shrinkage control by measuring moisture content and temperature at several points throughout the silo.

Level Monitoring

Tracking inventory in silos is an important component

Using our software and automatic mechanical level sensor makes it easy to know where materials are located and how much there is.

Aeration Control

Automatic fan control optimizes grain quality

Optimize grain moisture and temperature. Avoid shrinkage. Our temperature and moisture monitoring in combination with ambient temperature and humidity data starts/stops the fans automatically.

CO2 Monitoring

CO2 Sensors can provide early spoilage detection

Insects and moulds are organisms that respire and release CO2. The gas will travel to the headspace of the silo due to the internal upward flow of air.

Head Space Monitoring

Avoid condensation and wet grain on the grain surface

Roof ventilation fans are controlled by data from the headspace sensor and dew point is computed from temperature and humidity.

Ambient Monitoring

Monitoring weather conditions provides great control for aeration

The weather station keeps a constant eye on ambient conditions. Ensuring that only air of the correct properties is used for aeration.

Silos Monitoring System Software

The software will process all information collected by the sensors and display them using a friendly and intuitive UI. Through our software, you will know about the smallest change in your storage facility and you will be informed about any critical issue to react immediately and avoid any damages to your stored crops.

How the software works:

- Access the system anytime and anywhere using a PC, smartphone or tablet etc.

- Increase safety. With one system you can control multiple sites from anywhere in the world.

- Centralised system. Achieves high security and protection of data while being easy to manage and maintain.

- Use the automated reports. Save worktime by letting the software generate valuable insights for you.

- No software, backup or server maintenance as we handle this for you.

- We guarantee the safety of your data.

Software Benefits

- Intuitive, modern graphical interface allows quick and easy interpretation of data

- Real-time data – telemetry, monitoring and control 24/7.

- Real-time 3D visualisations quickly illustrate where problems occur in the silo.

- REST Interface for integration with third-party systems and an open system that gives developers access to advanced computations.

- Be alerted by e-mail to the slightest change in your crops, even when not currently using the software.

- Full historical chart for deeper insights into trends.

- With our software you are able to control multiple sites at the same time.

Our system has the following certificates:

- ISO 9001 Certificate

- ATEX Certificate

- European and UK Conformity

- Eurasian Conformity

Quick return of investment

With AgroLog grain bin monitoring systems, you secure crops while also ensuring a quick and secure return of investment.

AgroLog software will help you manage and control multiple facilities in one unique dashboard.

By securing your crops and reducing the waste, you maximise your profits.

Our grain bin monitoring systems secure your stored crops and reduce the waste to the minimum.