DRYING

The quality of the grain is the main factor that will affect its value in the market, this quality is sensitive to all the post-harvest processes, such as drying, handling, … [+]

CLEANING & PRE-CLEANING

Throughout Southeast Asia, the degree of impurities in the grain arriving at the facilities is very high, in addition to a high moisture content. Both of these… [+]

CONVEYING - HANDLING

Our conveying equipment handles a vast variety of bulk materials, ranging from agricultural products to industrial commodities and raw material … [+]

STORAGE

The design of the cylinder and roof of our silos by our engineering department has been made seeking to optimize its strength and durability. Another important … [+]

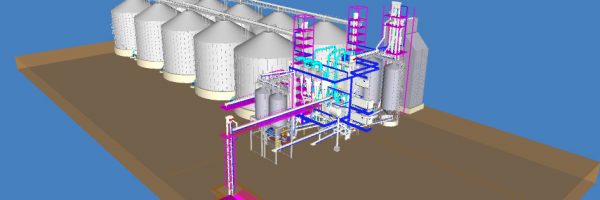

METALIC STRUCTURES

The integral grain storage facilities have incorporated new cutting-edge technologies in all areas related to the transport and storage of materials … [+]

AUXILIAR EQUIPMENT FOR GRAIN FACILITIES

The design of the cylinder and roof of our silos by our engineering department has been made seeking to optimize its … [+]

Innovative Equipment

We have the right technology to enhance quality and the right team to bring it all together

Personalized Solutions

Our process is designed with you at the core. From vision to reality and beyond, our team stays connected with yours. Giving you peace-of-mind with an expert at your side.

Western technology

"Integral solutions for reception, cleaning, drying and storage for the agricultural sector, biomass, malting plants, cereals, milling and feed mills".

Western technology

"Tailor-made projects for our customers' needs".

Western technology

"European technology at the service of the agri-food industry".

No project is too big or too small

From the cultivation, the harvest, the storage, the commercialization and its consumption there is a long way that in theory, seems simple, but there is a something that tells us the opposite. 40% of food produced in the world is lost in the processes that go from harvest to the final consumer and one of the main reasons is the lack of adequate infrastructure that guarantees good storage, transport and distribution conditions. 40% of food produced in the world is lost in the processes that go from harvest to the final consumer and one of the main reasons is the lack of adequate infrastructure that guarantees good storage, transport and distribution conditions.

That is why our main objectives are: Minimize losses of grain quality during the post-harvest stage, guarantee the safety of the raw material for the agro-industrial process, improve the safety of the workers involved in the post-harvest processes and reduce the environmental impact.

Our equipment are designed to be used in multiple sectors such as agriculture, biomass, brewers, feed mills, cereal trading and milling.

Consultation without

obligation

Our Suppliers & Partners

Driving technology for leading brands

NEWS

Post Title 3

From the cultivation, the harvest, the storage, the commercialization and its consumption there is a long way that in theory, seems simple, but there is …

Post Title 2

From the cultivation, the harvest, the storage, the commercialization and its consumption there is a long way that in theory, seems simple, but there is …

Post Title 1

From the cultivation, the harvest, the storage, the commercialization and its consumption there is a long way that in theory, seems simple, but there is …