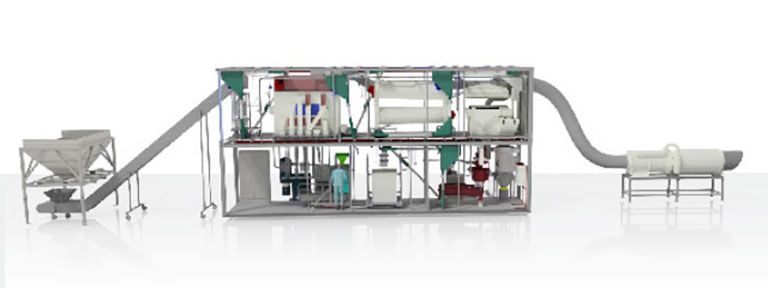

Compact Seed Plant

Western Technology offers the world’s very first seed processing plant that is fully pre-assembled and tested in the factory for shipment to clients around the world.

Product Overview:

Western Technology offers the world’s very first seed processing plant that is fully pre-assembled and tested in the factory for shipment to clients around the world.

Seed producers can minimize their risk when entering new markets by choosing this plug-and-play solution before investing in a permanent plant. Our processing plant can be operable within a few days on-site and can be easily transported to another site if needed.

Building requirements are very few: as only a leveled ground plate and roof are necessary to place the container plants.

The compact plant comes pre-assembled in two tailor-made 40 feet high cube containers. The plant is fully automated by means of a PLC-controlled switchboard that digitally contains all machines’, manual, spare parts, and service lists. Additionally, it provides service warnings for all the equipment according to the hours of operation of the plant. Online service to the PLC is possible via the internet.

- A central vacuum system is included for simple and quick cleaning of the entire plant. Additional screens and indented segments come in racks for safe storage. In front of each machine, a large double-door grants optimum access for daily works, service, and maintenance.

- A catwalk gives easy access to the upper container. It is shipped along with other auxiliaries, such as the intake pit, inclined feeding belt conveyor, and cyclofan. In two extra 40” containers that can be used for storage.

- Finished seed can be filled in small bags from 10 to 50 kg in the bagging line, equipped with a sticher and belt conveyor for finished bags. Alternatively, the seed can be filled in big bags by means of a suitable platform scale and hanging frame.

- The chemical treater room is isolated and can be heated.

- Upon request, Western Technology can also offer an in-house built Diesel Generator for the main supply to the entire plant. Optional containerized filter plants for aspiration are available to fulfill any local requirements.

Compact Seed Plant Equipment:

- Intake pit and belt conveyor (for simple and quick feeding of the processing line)

- Pipe magnet (to remove metallic parts)

- Finecleaner (to remove big, small, thick, thin, and light impurities)

- Indented cylinder (to remove short and long impurities)

- Gravity separator (to remove light impurities and kernels with low germination capacity)

- Cyclofan (for central aspiration)

- Continuous Chemical Treater (for a chemical treatment to protect kernels)

- Filling Stations (either in 10-50 kgs bags or in big bags, or both)

- Compressor (to feed pneumatic drivers and for cleanout)

- Central Vacuum system (for housekeeping)

- PLC Control Unit (for fully automatic operation of the plant)

- Container Rack (containing all the equipment including stairs and catwalk)