Buffer Silos

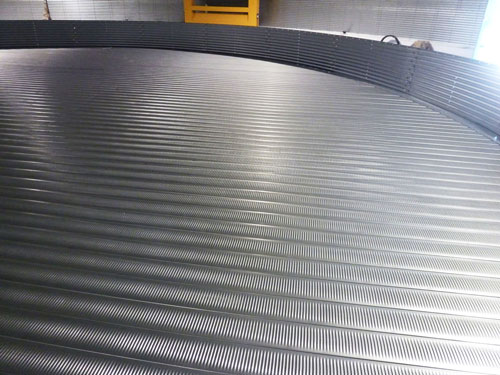

Buffer silos or reception silos can have a flat or conical bottom, and a ventilation system that adapts to the climate, the product to be treated, and the silo capacity.

Product Overview:

Some readers may wonder why we have included buffer silos in the drying section. But nothing could be further from the truth, it is in the buffer silos (before the product reaches the dryers) that the drying process can be said to begin.

The founder and designer of SAN JOSE dryers have shown us the valuable contribution of buffer silos and tempering silos in the drying process. Not varying cereal temperatures abruptly, making a slow but continuous drying process, avoiding the product passing through the dryers several times to reduce its temperature, etc… all of this is possible thanks to the inclusion of these additional systems in our industry.

Air is used as a tool for drying rice by forcing large quantities of air through the grain mass, so our buffer silos are equipped with all kinds of sensors and aerations for maximum control of the start of drying.

Buffer silos or reception silos can have a flat or conical bottom, and a ventilation system that adapts to the climate, the product to be treated, and the silo capacity.

Advantages of using buffer silos before the dryer machine:

- Aside from allowing us to work the reception of product at high speeds (higher than the drying capacity) to give a quick exit to our barges or trucks that bring the product.

- The main advantage will be the homogenization of the humidity of the grain. This will facilitate a more homogeneous drying process.

- Ventilation will make it easier for the grains to lose some moisture when they come with high percentages, and we will minimize the hot spots in the grain.

The fans in the silos cannot work if they are not practically full, as these fans are designed to work at sufficient pressure to overcome the column of grain when the silo is full, which is why, to make the most efficient use of this system, we must install two or more silos, so that at least the product can be ventilated for a few hours while our second silo is being loaded.

Western Technology will carry out a study according to the needs of your product/s to offer you the most suitable system.