Continuous Flow Industrial Dryers

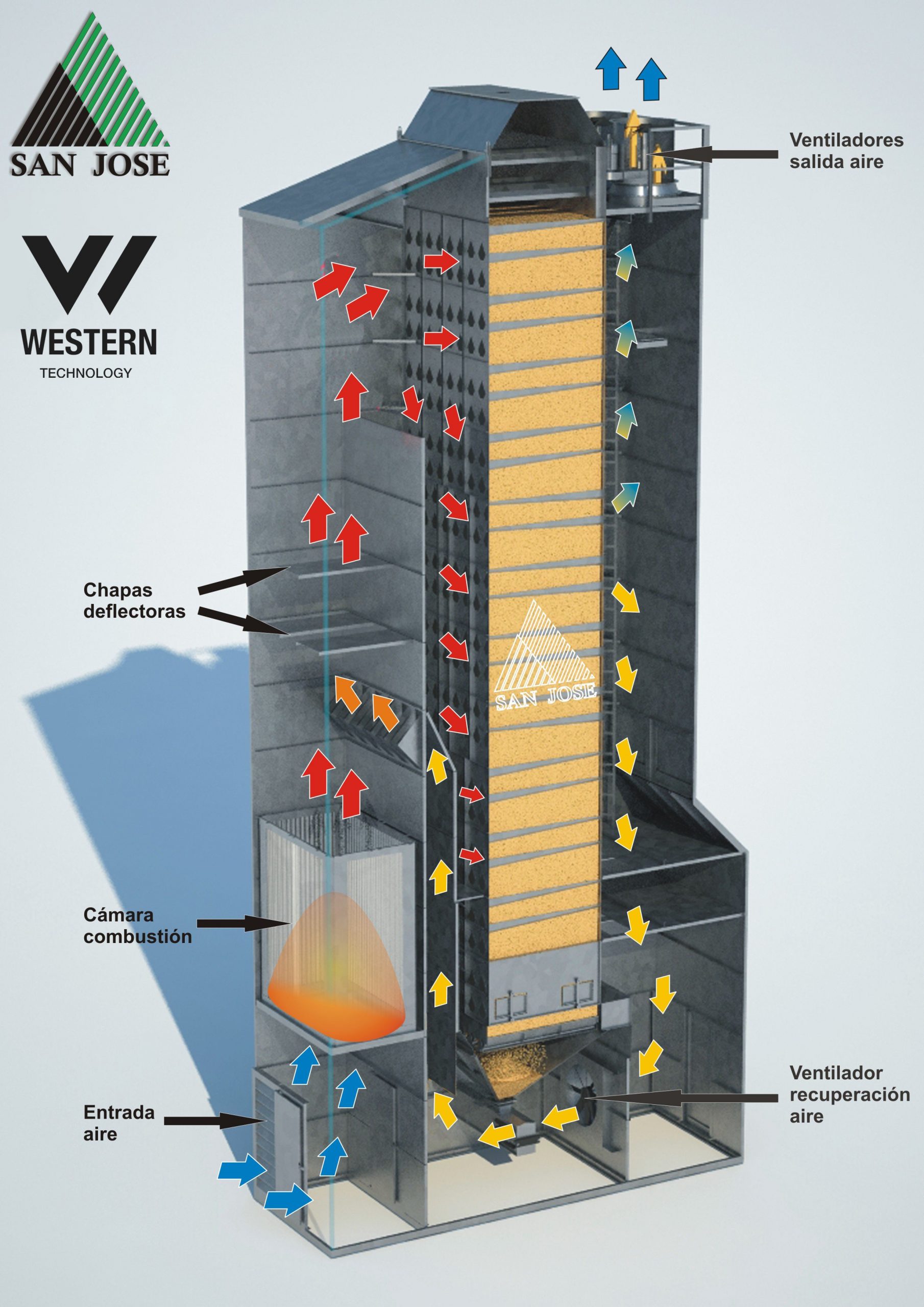

We work with a vertical industrial dryer with a high degree of energy efficiency, thus achieving highly effective drying. Its modular design allows us to adapt to the needs of all our customers.

Product Overview:

- Easily expandable modular system, offering a wide range of yields.

- Highqualityy galvanized steel construction with anti-corrosion protection.

- Mixed crosscurrent drying system, by tronco-conical air-roofs that make possible a more homogeneous drying of the grain.

- Self-cleaning pneumatic unloading system will minimize broken grain.

- Heat generation systems with direct and indirect attack monobloc burners, air vein burners, or adaptation of the dryer to biomass furnaces (rice husks, coconut husk, wood chips, pellets, etc…).

- Axial fans on the roof with high yield and low consumption.

- Humidity and temperature control probes, capacitive levels, thermovelocimetric sensors.

- Energy recovery system. Recovering part of the air already heated from the saturated air zone and reducing air heating consumption.

- Adaptation of our dryers to continuous drying using tempering silos.

- Solutions for the removal of dust and impurities.

- Special safety package for drying oilseeds.

- Statistical control software and total or partial automation of the whole system using PLC, with touch screen control panel or by, external PC (according to the customer’s requirements).

High-tech inside the dryer in detail:

SAN JOSE dryers allow higher temperatures to be used than their competitors without affecting the quality of the grain, thanks to the design of the central module through which the grain descends.

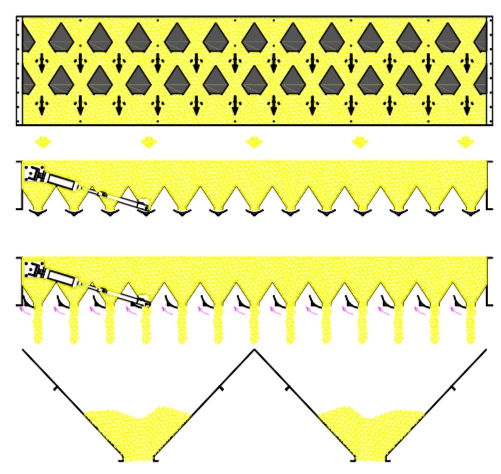

While in almost all the dryers on the market the air-roofs are horizontal (cheaper to manufacture and easier to transport), in SAN JOSE dryers they are tronconical.

What are the advantages of this design?

Due to the shape of the air roofs, the grain descends by gravity in a zigzag pattern inside the dryer, thus ensuring that the same grain is not always in contact with the hottest flow, obtaining a more homogeneous drying and allowing higher drying temperatures without damaging the product.

In addition, its design ensures a constant airflow velocity at any point in the drying column. As the tronco-conical design would help the farthest point to maintain air pressure. This makes optimum use of the hot air, obtaining maximum saturation of the hot air, allowing more homogeneous drying, and will minimize energy consumption.

One of the main difficulties of the dryers is that the impurities in the grain and its humidity, added to a drop between the aeration air-roofs, tend to slow down the natural descent of the grain. SAN JOSE dryers minimize this problem as much as possible, thanks to the technology used to extract the grain from the dryer.

The extraction system is made up of half-channels that act as gates and which pivot thanks to the action of a pneumatic piston, discharging intermittently, and releasing a large quantity of grain in a short interval of time, which guarantees a dynamic and regular flow of grain. In this way we prevent possible blockages and hollow out the mass of grain so that the hot, saturated air flows homogeneously throughout the grain column, thus achieving economical and more homogeneous drying, as well as reducing the percentage of broken grain very considerably in comparison with other systems on the market.