Aeration Systems

The centrifugal and axial fans supplied by Western Technology are manufactured under European standards with IE2 certification, ensuring their energy efficiency.

Product Overview:

The aeration of grain cereals is a fundamental practice to preserve their quality during storage. Properly used, this technology allows to control the temperature of the grain and limit the development of insects, thus avoiding deterioration and losses.

We use different aeration systems depending on the client’s needs:

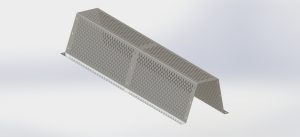

- Channels made at the base of the silo in civil works and covered by our aeration system, occupying approximately 15 to 18% of the surface of the flat-bottomed silo.

- Fully perforated horizontal floor resting on a structure of hot-dip galvanized supports covering 100% of the surface area of the flat-bottomed silo.

- Inside perforated cone: internal hopper system supported by a structure of pillars, beams, and bracing. It allows complete ventilation of the floor with the unloading conditions of a hopper. Its inclination can be 30 or 45 degrees. Available for diameters from 5m to 9m in diameter, and maximum height of 14 rings for flat bottom silos.

- Aeration system in conical bottom silos, with double inverted cone for silos up to a maximum diameter of 8m.

- Hopper aeration channel system for conical silos.

- The roof air vents are optionally available with the use of helicoidal exhaust fans.