Silo Inventory Management

The Inventory Management System truly brings control over your inventory to your fingertips

Product Overview:

The Inventory Management System truly brings control over your inventory to your fingertips.

The System Software provides the user with valuable insight into what is happening on-site, in the silo, and on the book. By balancing and synchronizing these three important factors the System gives the Silo owner the capability to balance book stock positions to what is physically happening in the silo.

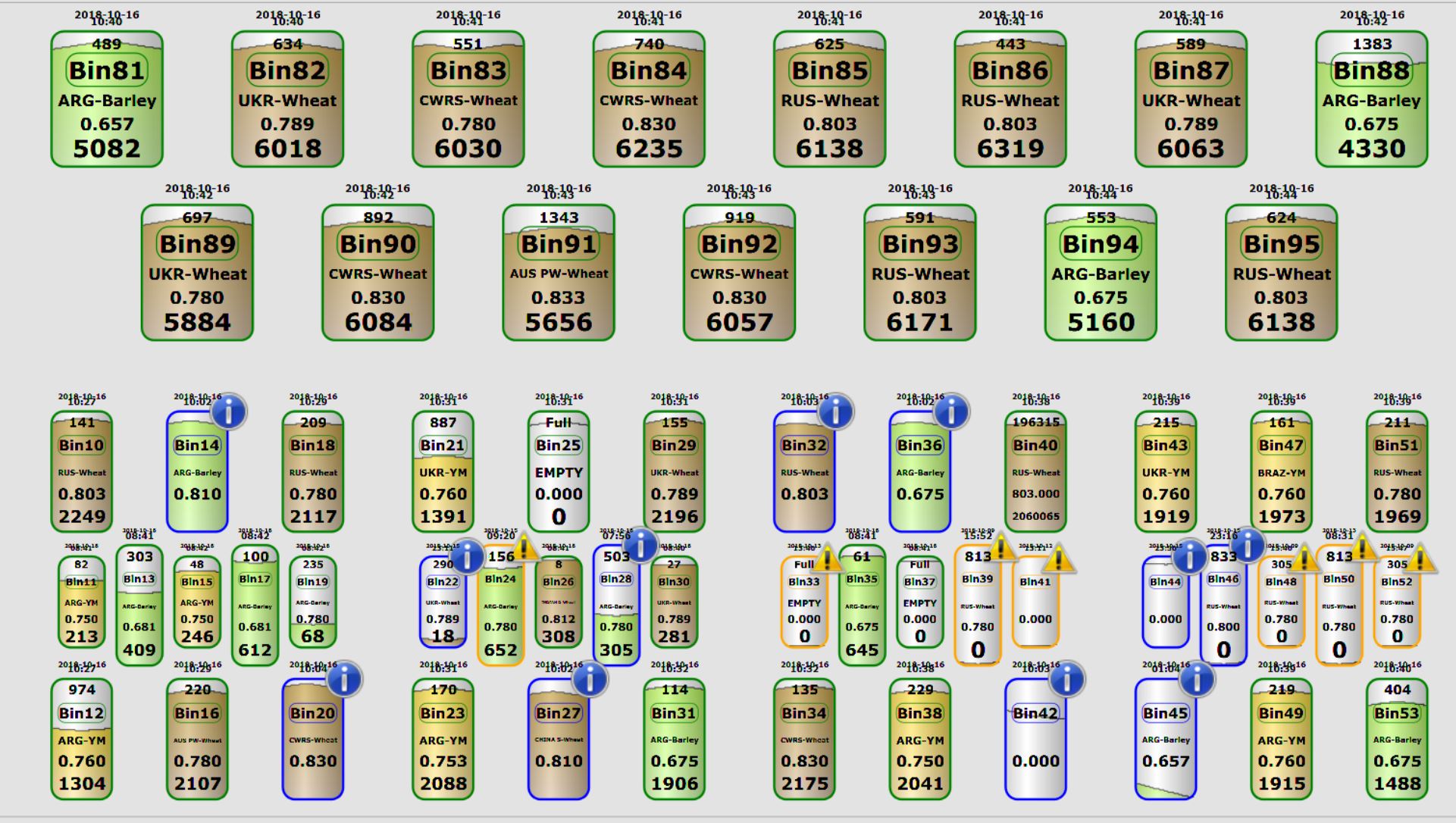

Stock management begins by having a holistic daily overview of what is happening on site. Bin location and number, as well as grain type stored, its grade, density, and other grading criteria, are very important. This information together with an infrastructure of laser scanning devices that measures the occupied volume on an ongoing basis creates the backbone of the System.

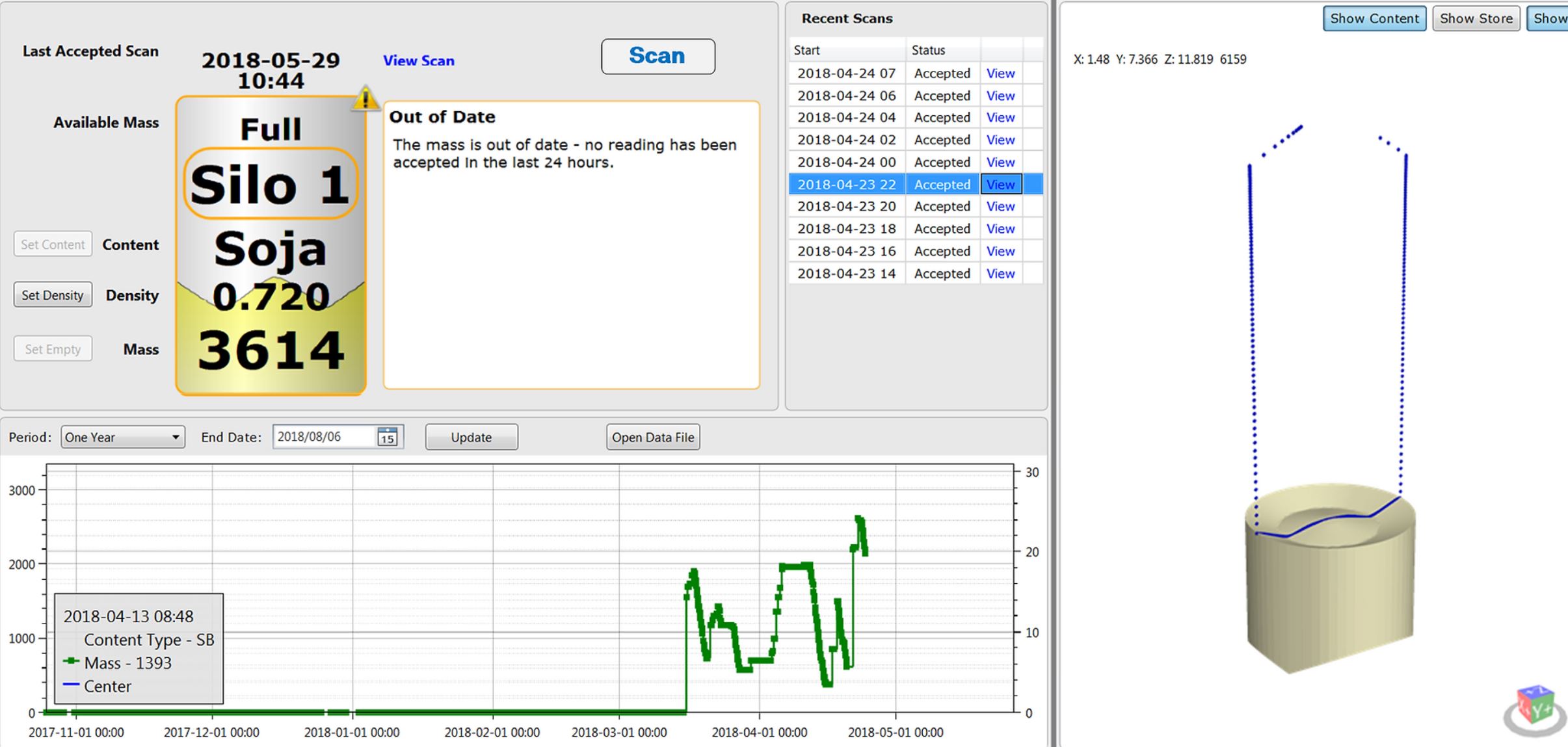

The Dashboard Software offers another dimension to silo bin data by selecting any of the bins on the Dashboard. All historically published scans data is available on this page as well as the mass, volume, and density at the time of measurement. Bin allocations for product type, density, and grade are done on this page. The Single Bin View page also gives the operator the capability to look at the last ten scans published.

This page also hosts the current status of the hardware and software for the bin. The status icons and message tab gives the current status in terms of reporting schedule, infrastructure soundness, out of date scans, dusty, or overfill statuses inside the bin. All of this data offers validity to the data reported and will indicate to the operator where his system or data could be compromised.

- Balance your book to physical bin stock on a daily basis.

- Identify Surplus and Shortage stock positions over time.

- Remote Head Office oversight and awareness.

- Trending of data.

- ART Dashboard can report to subscription-based ART Cloud Management platform for multiple site data availability on one platform.

- Full-grain movement history per bin.

- Facilitation of temperature data per bin (optional)

- Inventory Balance report published daily in .pdf format. This report details the tonnage, volume measured and bulk density applied to each bin at the time of the report.

- System Health report published daily in .pdf format. This report details the hardware and software functionality status.

- Events report published daily in .pdf format. This report provides detail in terms of any changes applied on site to change the stock position. This could be bin allocations, density changes, grade changes, grain type changes applied.