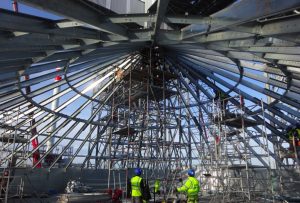

Engineering

The design of the cylinder and roof of our silos by our engineering department has been made seeking to optimize its strength and durability

The design of the cylinder and roof of our silos by our engineering department has been made seeking to optimize its strength and durability. Another important aspect considered during the design process has been to optimize the amount of steel used to lighten the total weight of our silos.

The reliability of our manufacturing process through the use of CNC punching machines, ensures that the holes of the screws for the joints fit perfectly. Corrugated sheets are manufactured from steel coils, which are supplied by quality-controlled steel suppliers.

All our silos are made of high resistance galvanized steel S450GD, according to EN 10346, with a high elastic limit and a minimum Z600 coating, equivalent to 600 g/m2 of zinc. High elastic limit steels have the same performance as conventional steels, but with less thickness and therefore less weight. They are ideal for the manufacturing of structural elements and parts that will be subjected to high dynamic and static stresses

The use of high resistance steel reduces the weight of the silos providing advantages in logistics, assembly, and handling of the components in the place of assembly and the use of Z600 coating will extend their useful life. They are ideal for the manufacturing of structural elements and parts that will be subjected to high dynamic and static stresses.

Other important characteristics of this type of steel are:

- It has a high degree to draw

- It admits hot galvanized processes

- Excellent bending and surface quality

- Good weldability with excellent strength and hardness in the heat-affected area.

- High impact resistance, providing fracture resistance.

All components are designed in 3D, analytically calculated, and structurally verified by Finite Element Analysis (FEA).

The two main norms used for the structural integrity of the Silos are the European EUROCODE and the American ANSI.

Norms EUROCODE / ANSI

In silos calculated according to EUROCODE, the loads and pressures acting on the walls of the silo are based on EN 1991-4 Actions on Structures: Silos and Tanks, and when calculated according to ANSI, the grain loads are based on ANSI / ASAE EP433.

Structural evaluation

The structural evaluation of the walls of the silo, whether we use one norm or another, is based on the following norms:

- EN 1990 Basis of Calculation of Structures.

- EN 1993 Eurocode 3: Steel structures.

We have storage silos under both standards depending on the customer’s needs or the requirements of the country of destination.

We also carry out design engineering for specific projects that go beyond the standards detailed in the catalog.

“Our flat bottom silos, with corrugated walls are designed to store different types of cereals and/or granulated materials in bulk.”

Our flat bottom silos with corrugated walls are designed to store different types of cereals and/or granulated materials in bulk. With diameters from 3 m to 32 m and capacities from 30 m3 to 26,000 m3, our CERES series silos are designed to ensure safe storage for a wide variety of free-flowing products, even in very long storage periods. The corrugated steel sheets of the silo body are manufactured from pre-galvanized steel coils, which are supplied by approved steel suppliers according to our quality system. The main characteristics of the steel used for its manufacture are S450 + Z600 according to EN-10346.

The corrugated steel is made up of waves 106 mm long and 13 mm deep, providing a useful sheet height of 1166 mm and a useful length of 3140 mm. The thickness of the wall sheets goes from 0.8 mm to 3.5 mm. If because of calculation requirements, a greater thickness is required, combinations of different thicknesses will be used until the necessary strength is achieved.

The external galvanized stiffeners in the silo wall transmit the vertical load of the grain and silo self-weight to the foundation.